Managing disparate automation systems presents major challenges

Modern warehouses and distribution centers with automatic storage and conveyor technology systems implement MHE from multiple vendors. They also find that automation technology requires a substantial investment, which they are willing to make to:

- Increase throughput and maximize capacity of warehouse operations.

- Trace and remediate malfunctions as quickly as possible.

- Immediately adjust material routes in case of malfunctions or receipt changes.

- Ensure visibility of materials along the entire automation chain.

However, a multi-vendor MHE infrastructure makes it virtually impossible to run the costly automation equipment as a unified system, much less optimize it. It also lacks end-to-end visibility of the automation chain.

WCS integrates control of your warehouse automation

Körber’s warehouse control system is vendor-agnostic and supports all material handling technologies. This creates a single point of data and communication amongst MHE, WCS and WMS, and provides centralized control and management. It also ensures continued material flow if individual devices fail. Capabilities include:

- Management of all common vendors and types of conveyor and storage technology, such as shuttle systems, high bay warehouses, automatic storage and retrieval systems (ASRS), and many others.

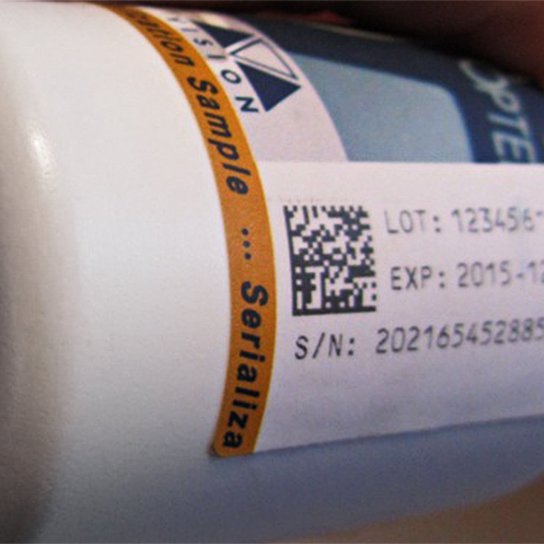

- End-to-end visibility of the automation chain, which enables tracking of the material flow and barcodes through the system.

- Support for all common workflows: basic automation, hybrid automation-workforce configurations, and complex fully-automated operations.

- Constraint-based algorithms, which enable optimization strategies such as dynamically selecting the optimal transport route or interleaving, and adjusting material routing in case of equipment failures.

- Offline emulation mode, to simulate automation scenarios in a non-production environment.

- Database-driven architecture, which enables high scalability to support exponential growth of transactions.

- Intuitive, graphical dashboards that visualize data and provide actionable insights to continuously improve material flow and equipment ROI.

The Körber difference

Körber’s warehouse control solution has been available for decades – almost as long as automation has been employed in warehouses and distribution centers.

We have continuously evolved our WCS with unique functionality, to create a vendor-agnostic, best-of-breed software solution. Our experience extends beyond the software and includes implementation services to customize the solution to your environment. Our team will partner with your operators to help you unify the management of your automation systems and maximize its ROI.