Palletizing challenges in modern manufacturing operations

The demands of modern manufacturing and production make it increasingly difficult for companies to grow, scale, and accelerate their operations efficiently and cost-effectively.

One solution to these challenges is palletizing, the process of automatically stacking products in various packaging options onto pallets for more efficient storage and transportation. By implementing palletizing systems, companies can streamline operations, manage labor requirements, and increase worker safety. With the right palletizing equipment and expertise, companies can realizeimprovements in productivity and profitability.

Our Palletizing Benefits

- End-to-end solution: We deliver complete automated palletizing solutions, which means the mechanics, hardware and software are all closely attuned to each other.

- Tailored delivery: Our palletizer solutions are designed with the customer in mind, accounting for the unique requirements of their market, their business, and their objectives.

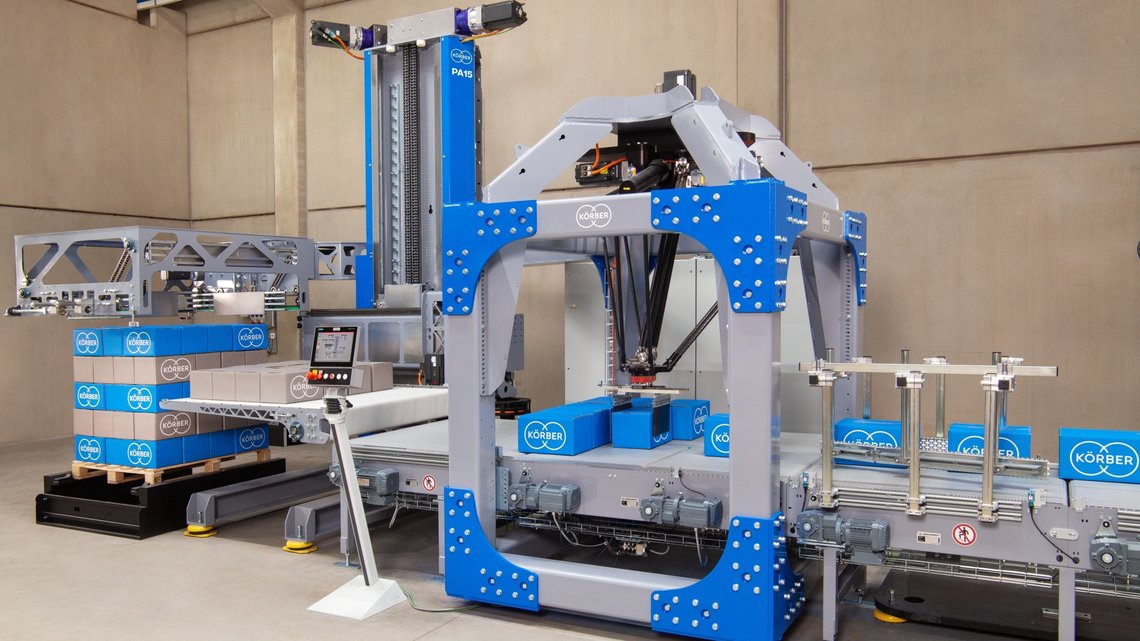

Layer Palletizers

Meeting the demands of today’s multi-channel, multi-fulfillment market creates several palletizing challenges, particularly for small-to-medium sized production plants. Our Layer palletizers are precision-designed to handle high throughputs and are suited for limited production plant spaces.

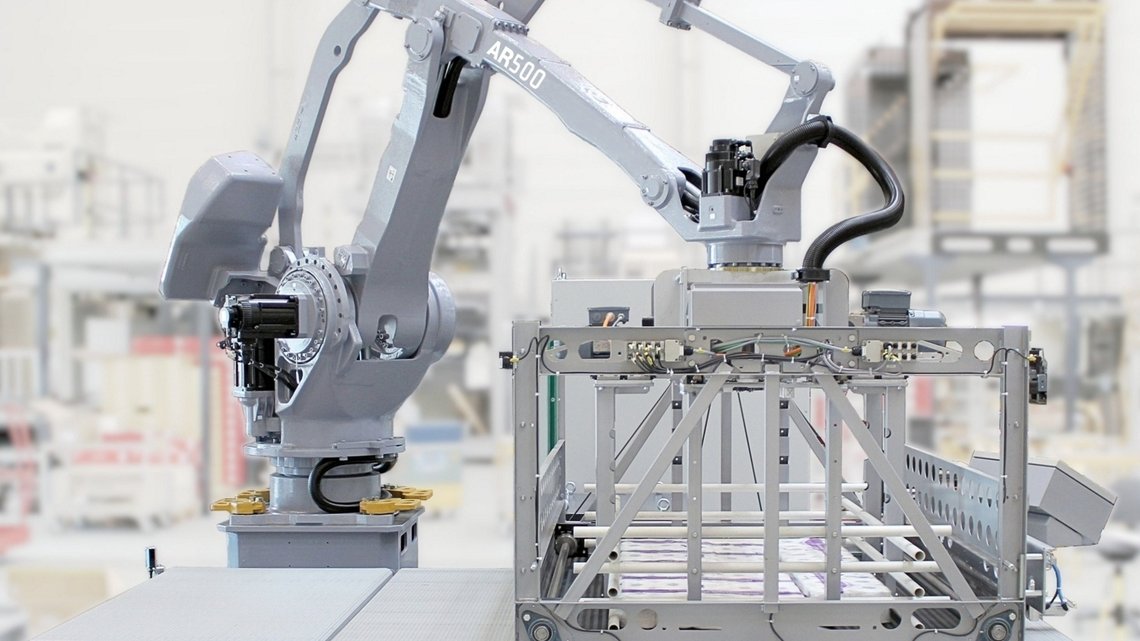

Stack Palletizers

Designed for limited spaces and multiple product formats, the case stacker is the first choice for fully automated stacking and palletizing. Not only can it stack palletized plastic cases, meat crates and nestable carton trays (including trays with stacking corners), but it can also stack cartons and bakery baskets without pallets.

Make every pallet count

In today's fast-paced supply chain, optimizing every step is crucial for efficiency and cost savings. Manual pallet load calculations can be time-consuming, prone to errors, and ultimately lead to wasted space and higher shipping costs.

Our user-friendly calculator takes the guesswork out of pallet loading. It's a powerful tool designed to streamline your operations and maximize profitability.