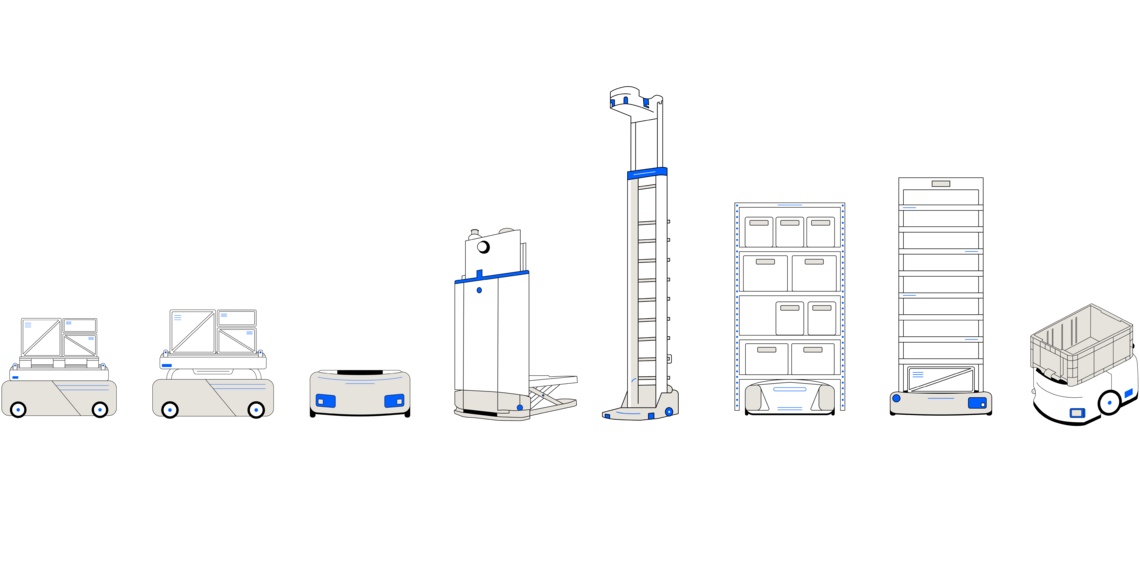

Welcome to the future of mobile robotics

In the ever-evolving world of logistics and warehousing, efficiency is paramount. At the same time businesses need to quickly adapt to changing requirements.

Here, mobile robot-based systems revolutionize the way businesses operate, delivering unmatched scalability and flexibility.

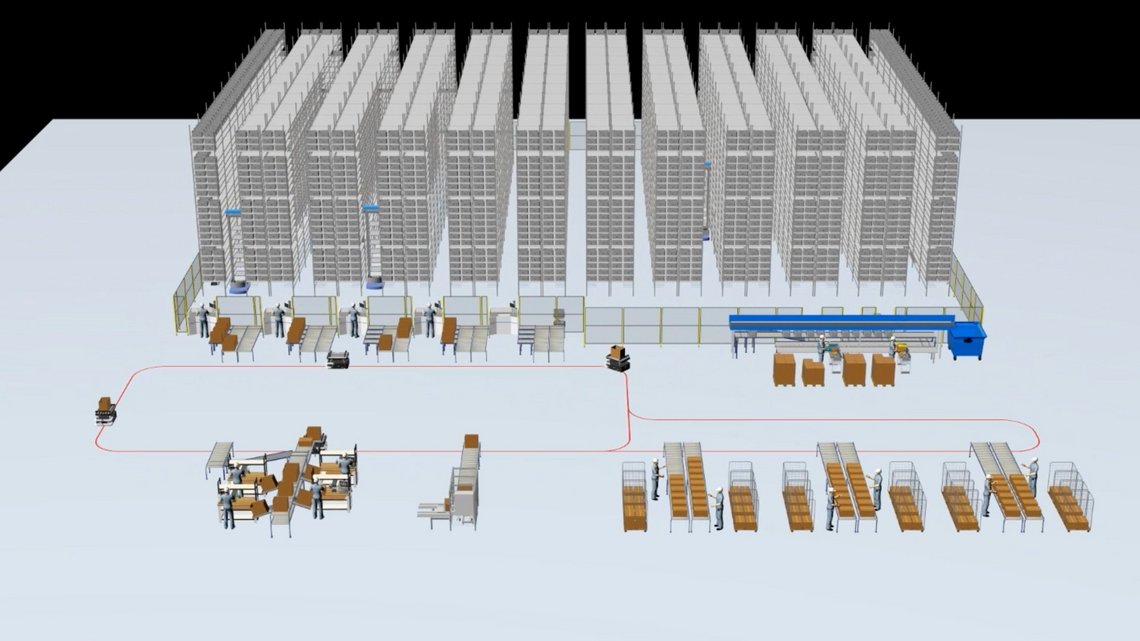

Transport

Small goods: handling of order cartons in a G2P solution; i.e., connecting picking with packing.

Pallets: connecting AR/RS systems with manufacturing areas.

The challenges mobile robots overcome

The logistics industry faces growing pressures, from labor shortages and rising labor costs to managing an ever-increasing number of products and the relentless demand for on-time delivery.

Mobile robots offer a powerful solution to these challenges. By automating (repetitive) tasks, optimizing workflows and the ability to operate 24/7 with precision, mobile robots help to enable timely and efficient deliveries, empowering logistics companies to meet customer expectations while staying ahead of the competition.

Why choose Körber Supply Chain Automation for your mobile robot integration?

When it comes to optimizing your operations with mobile robotics, Körber Supply Chain Automation stands as your one-stop-shop. Our extensive portfolio allows us to provide tailored automation strategies designed to meet your specific business challenges. Whether you're looking to enhance order fulfillment or streamline material flow, our team ensures that every solution we implement delivers maximum performance, efficiency, and scalability.

From the initial design to support and ongoing optimization, Körber is with you every step of the way and handles every aspect of your mobile robot integration. Discover how we can future-proof your operations.