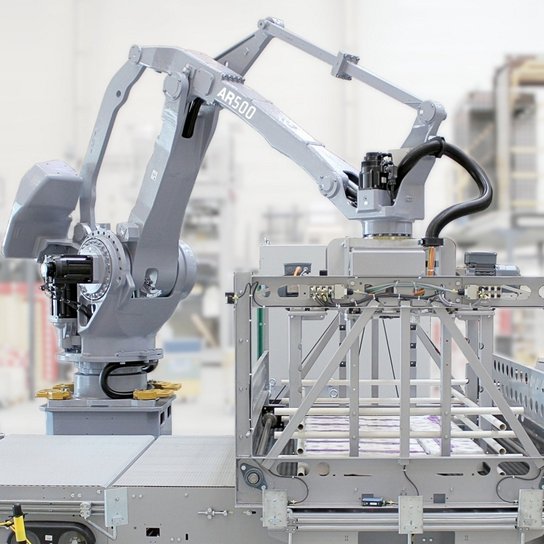

Flexible robotic picking of pallet layers

The Layer Picker Robot is an extremely versatile solution for fully automated picking of pallet layers. The articulated robot arm moves the Layer Picker head in all directions, making it equally well suited for pallet-to-descrambling and pallet-to-pallet picking.

With up to eight pick-and-drop positions, it can achieve a highly efficient pallet flow, helping to maximize productivity in most logistics solutions.

Future-compliant layer picking

The more complex and diverse the packaging is, the more suitable the Layer Picker is for the task. It is unique in its ability to pick – for instance – light, fragile display cartons with crisps in the same process as heavy PET bottles, open crates or empty pallets. It can automatically switch from one complex item to the other – from gentle handling to heavy load – without damaging the products.

It operates steadily and reliably in both ambient and chilled facilities, in temperatures ranging from 0°C to +40°C (+32°F to +104°F).

The technology has already proven its worth, with more than 600 installations worldwide. Looking to the future, the benefits of the Layer Picker make it a smart investment.

Our customers face many challenges: more demand for faster delivery, increasing variety of articles, fast-changing SKU profiles, labor challenges and lack of space. They are also tasked with managing increasing limitations on food and transportation packaging.

With its patented technology, the Layer Picker has mitigated the challenges of ever-changing packaging types for more than 20 years. Businesses are reducing their use of packaging material, especially plastic, and its versatility makes it future-ready.