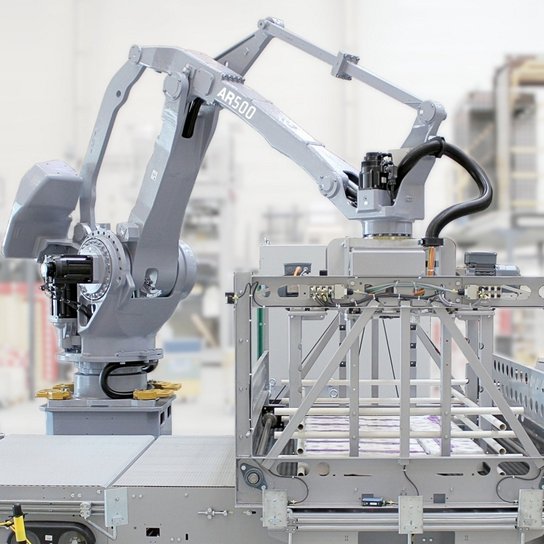

Automated pallet-to-pallet handling

The Körber Layer Picker Gantry provides an outstanding method for building mixed-layer pallets, made up of layers from many different source pallets. Its key advantage is its ability to hold a large number of source pallets statically, while the Layer Picker picks dynamically from above. This increases performance when creating mixed layer pallets, making it especially suitable for large facilities with a wide variety of SKUs.

Pallet outputs are known by many different names, such as customer pallet, mixed layer pallet, rainbow pallet, and sandwich pallet. The same goes for input pallet: single-SKU pallets, source pallet, inbound pallet. Whatever the pallet type, the Layer Picker Gantry can handle it.

Also in deep-freeze

The Layer Picker Gantry solution offers significant improvements to the working environment in temperature-controlled warehouses. It is adaptable to deep-freeze distribution centers with temperatures down to −28°C (−19°F). This makes it the perfect automation choice for the efficient handling of frozen produce and other perishable goods, as well as ambient temperature goods.

The labor challenges faced in the harsh environment of a refrigerated or freezing cold warehouse are well known. In this setting, Layer Picker automation improves accuracy, increases throughput, boosts productivity, and reduces overall warehouse labor costs.

Furthermore, it can help your business to scale and effectively manage larger volumes in peak periods.

Warehouse operations are also simplified and optimized due to the Layer Picker’s ability to pick up to 98% of all food retail product types. Using the universal head, it can gently pick light-and heavy-duty products (up to 450 kg), multiple layers, cartons with loose lids, open crates, plastic totes, and more.

The Layer Picker Gantry is primarily applicable for pallet-to-pallet handling; however, it can also be combined with our modular downstream equipment. Our experts can help you choose from our standardized modules and design a solution to fit your business.