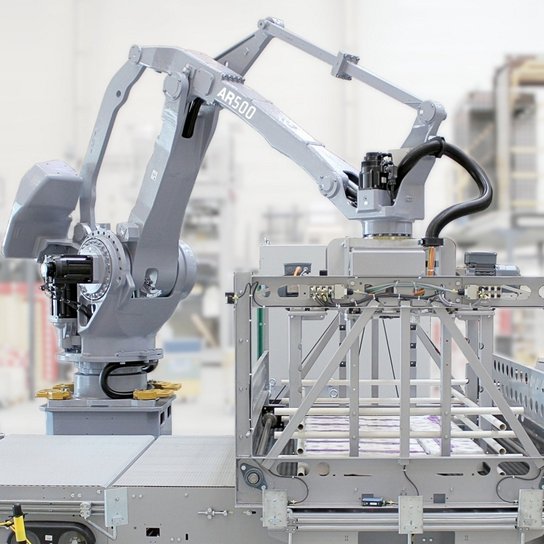

The ultimate de-palletizing technology

The Layer Picker Hoist is the go-to solution for high volume de-palletizing. It can pick a very high volume of layers and an extremely large variety of goods and is predominately used for pallet-to-descrambling, where layers are broken up into single cases. This includes complex items normally deemed unfit for automated picking (for example, fragile products, display cartons, PET bottles and layers with voids).

As well as being able to pick up to 450 kg/layer, the Layer Picker Hoist can operate in deep-freeze facilities. With operating temperatures ranging from −28°C to +40°C (−19°F to +104°F) the Layer Picker Hoist is a game-changer, when used to improve efficiency and working environment in these settings.

Unmatched performance with retail product layers

The Layer Picker has become the industry standard, thanks to its unmatched, proven technology and unique, patented suction and clamp picking method. No other layer picking technology can handle up to 98% of all product types in a food retail distribution center. The Layer Picker Hoist also offers other benefits, including high system availability, easy maintenance access, and adaptability to a host of high-volume de-palletizing requirements.

By introducing Layer Picker technology to your warehouse, you are one step ahead of new developments in packaging material and layer patterns. We have more than 600 Layer Pickers in operation 24/7 around the world, some in use for 20 years.

Risk-free de-palletizing in your solution design

The automation of layer picking and descrambling of product pallets into single cases is a complex process, requiring in-depth understanding of the technology involved. We offer that expertise, and can help you avoid significant risk by optimizing your de-palletizing layout.

Even if your Layer Picker and its auxiliary equipment make up just a small part of the process, the tasks it performs are crucial to the successful function of the whole intralogistics system. This is because most products pass through the Layer Picker and the downstream processes. Why wouldn’t you want to eliminate the worry of unexpected costs, when your systems can be streamlined through an expert sub-supplier?