The Layer Picker AMR (autonomous mobile robot) system is a fast, reliable and flexible way to handle automated pallet-to-pallet picking and create mixed-layer customer pallets. The system meets today’s need for scalability and high throughput by combining market-leading layer picking versatility with AMR transportation efficiency and flexibility.

The system meets the need for today’s high throughput by combining picking versatility with transportation efficiency. It is also highly compact, making it easy to deploy in any warehouse.

Ideal for FMCG, food retail and 3PL operations

The Layer Picker AMR is the perfect fit for operations with a large variety of stock keeping units (SKUs).

It is fully automated and tailored to deliver high-performance pallet-to-pallet handling, making it ideal for large, fast-moving consumer goods (FMCG) producers, food retail and 3PL providers.

As well as future-proofing operations, it helps manage staff shortages and meet shorter delivery times.

Mixed order pallet creation using the latest technology

The Layer Picker AMR is a complete standalone turnkey pallet-to-pallet handling system. The combination of industry-leading layer picker and AMR technology with state-of-the-art software optimizes its operation, as well driving high throughput, flexibility, and speed.

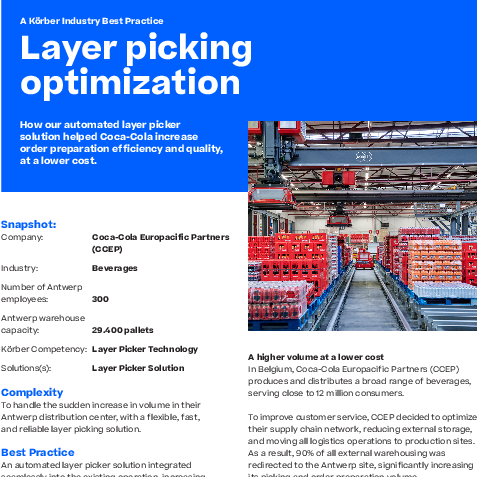

The movement of pallets to the picking area under the Layer Picker Mono Gantry is carried out by the AMRs. Compared to conveyor-based systems, this is a low-complexity, small-footprint solution, with a lower entry cost.

Designed for scalability and modularity

The Layer Picker AMR is designed to grow with the business. Being both modular and scalable, it offers flexibility during peak seasons. Users can simply add AMRs or pallet positions in the floor buffer, in- and outfeeds, and downstream equipment when demand increases.

This compact, modular system can also easily be integrated with existing systems and deployed in almost any warehouse layout. It is individually designed to customer needs using standardized modules. It is also scalable by width, length, and height, making it possible to up-scale without increasing warehouse footprint.

The Layer Picker technology gives you:

- Extremely versatile and simplified layer picking

- Proven and reliable technology

- Accurate and high-speed layer handling

- Minimized product damage compared to manual handling

- Future-proof, standardized and upgradeable technology

- Minimized footprint compared to manual picking

- Better workplace safety and ergonomics

- Stable, high-quality customer pallets

- Traceability – the system can track every SKU within every layer

- AI-enabled technology

- Capability to handle slip sheets, interlayer sheets and glued layers

- Secure and predefined interfaces to adjacent systems

- Complete turnkey solution including software and controls

- Lifetime services

Proven Layer Picker technology

Thanks to over two decades of engineering expertise, application development and innovation, the Layer Picker is the most versatile solution on the market today. It handles a uniquely wide variety of different SKUs using the same picking head, including complex items normally deemed unfit for automated handling.

A unique combination of suction and clamping enables it to pick layers with voids, fragile cases and heavy layers of crates. It can pick from multiple source pallets simultaneously to create an order pallet – up to 98% of all supermarket products, including crates, cans, PET bottles (carbonated and uncarbonated), and beyond.