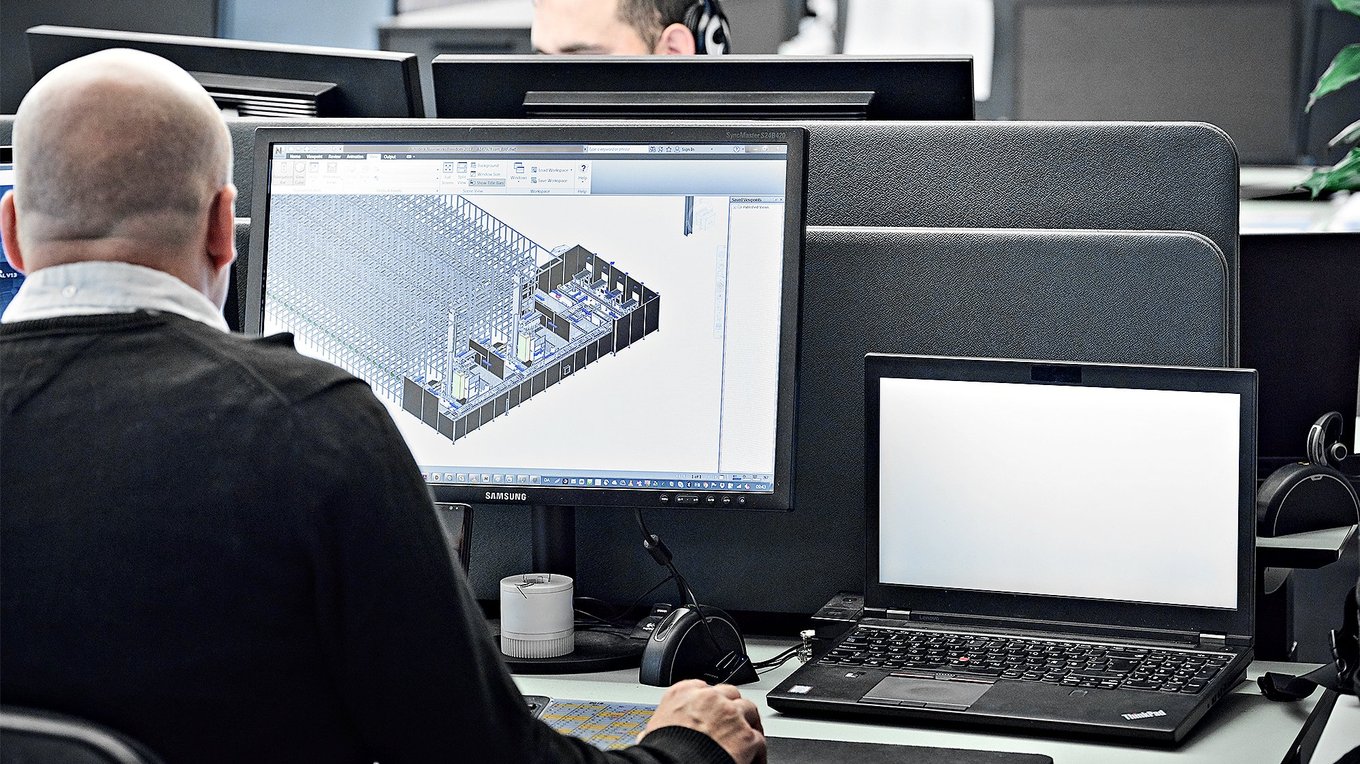

System Expansion and Retrofitting

Körber has a team of specialists dedicated to carrying out retrofits and expansion programs. This is great news if you are looking to modernize components or expand your current warehouse operations – without the cost and complexity of implementing a whole new system.

Expansion and retrofitting challenges

Organizations looking to grow or modernize their existing supply chain logistics systems without fully replacing them face challenges:

- If the original system supplier has retired the system, essential replacement parts are unlikely to be readily available.

- Without acquiring these spare parts, how can you modernize and future-proof your existing system?

- There may not be anyone at your original supplier who still has an in-depth knowledge and understanding of your current system

Gain access to equipment and expertise

Körber has access to all the necessary equipment and expertise required for a retrofit or expansion of your existing systems.

Our dedicated retrofit team will provide the right components at the right time. We will carry out your retrofit outside business hours so that there is no downtime and no impact on warehouse productivity.

During a retrofit or modernization of your warehouse, our team will implement and test your retrofitted solution when your system is not running in production mode (usually evenings or weekends). We will run rigorous hardware and software tests to ensure the updated system is running efficiently, and then we will switch over to production mode.

Our goal is to complete your retrofit or expansion without any impact on your warehouse production time.

Key benefits

Depth of knowledge

Our experts have an in-depth understanding and a wealth of experience in carrying out retrofits and expansions for existing warehouse systems. We know that your system is unique and we will gain a deep understanding of how your warehouse operates before implementing a solution.

The Körber difference

When it comes to your current warehousing system, you may have equipment and components that are no longer being manufactured. However, our team has an unparalleled depth of experience and knowledge of these systems, as well as access to spare parts. Plus, we’re equipment agnostic, so we work with all technologies, not just our own. That’s why our clients have complete trust in us to retrofit their warehouses.

System Expansion and Retrofitting in use

Berglandmilch

For this complex retrofit project, Körber successfully upgraded the customer’s cheese warehouse in Austria with state-of-the-art pallet conveyors and modern control systems. All aspects of the retrofit were completed without any interruption to operations.