Details

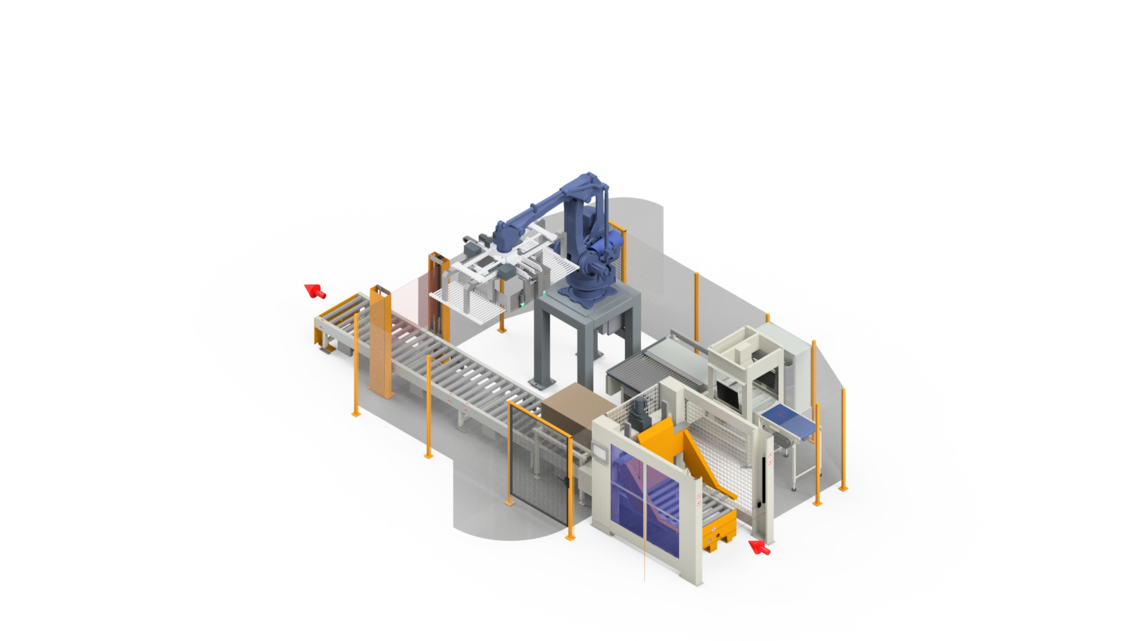

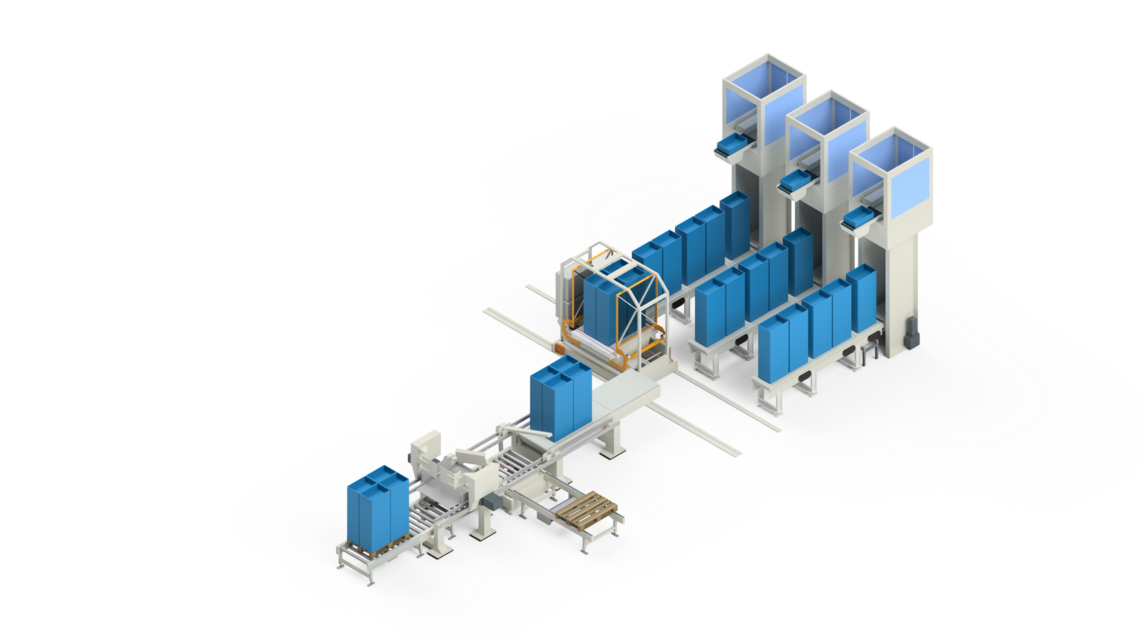

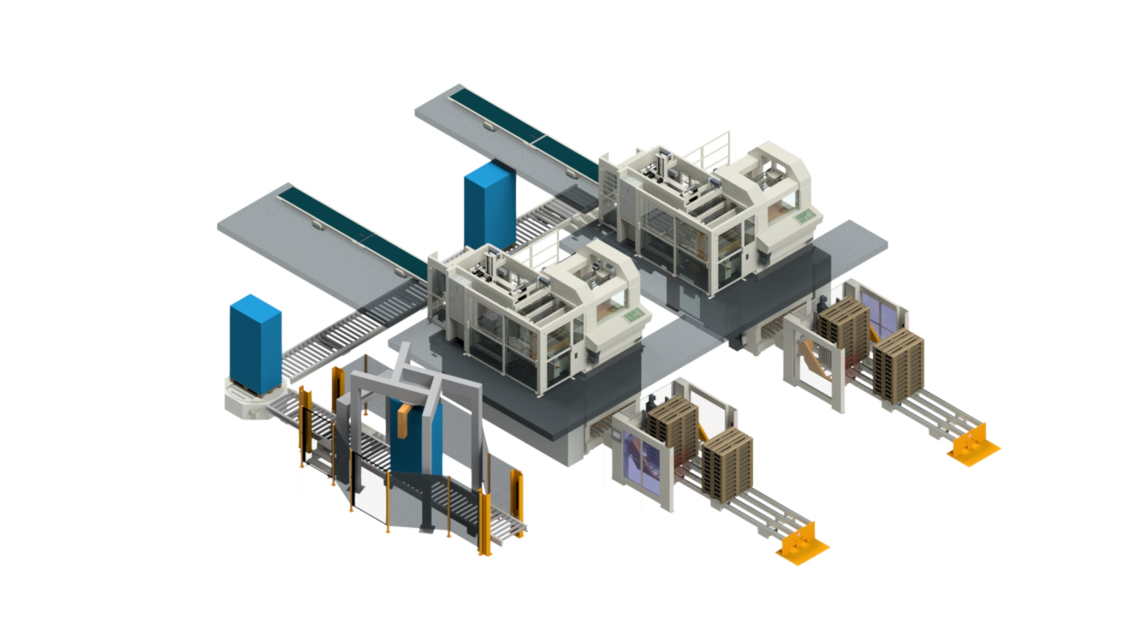

Perfect for palletizing bundles, cartons, and containers, the PA08 is well suited to display pallets for the hygienic paper industry. It can also be combined with other palletizers, either as a single-line palletizer or multi-line palletizer, to form a palletizing center.

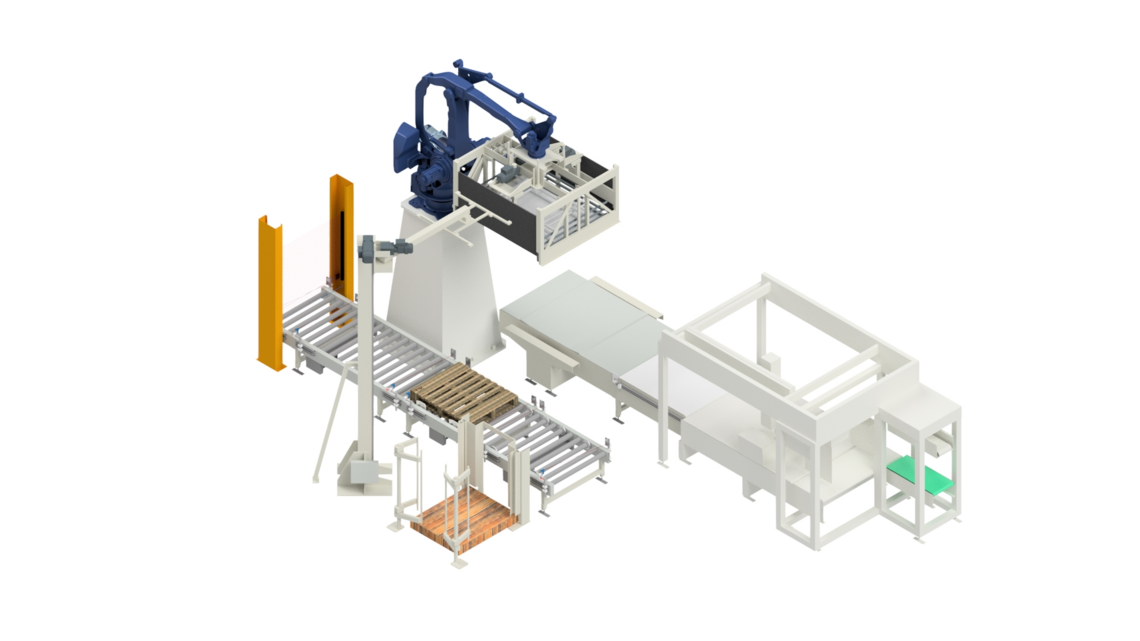

The PA081 features a lengthwise pallet run – crucial for palletizing bags. In addition to supporting both lengthwise and crosswise runs, the PA082 can handle heavier loads.

Benefits

- High output rate for a wide product range

- Precise operation supports direct production of sales-ready pallets

- Toolless format changes offer quick and easy product changeover

- Small footprint facilitates integration into existing palletizing lines

- Modular design adapts easily to any layout

- Extendable through our modular system