Efficiency in receiving systems is a major challenge

Many organizations face growing complexity in processing incoming goods:

- Shipment sizes are becoming more variable, while product ranges are broadening

- Growing product assortments and reduced inventory, combined with shorter lead times for outbound orders, are putting the receiving process under pressure

- Floor space restrictions, increasing transportation restraints and manual labor shortages are growing issues

Receiving requirements, processes and material flows vary widely between industries. Each shipment needs to be checked against its purchase order for both quantity and quality. Different goods need sorting and sometimes repacking before being stored in your warehouse.

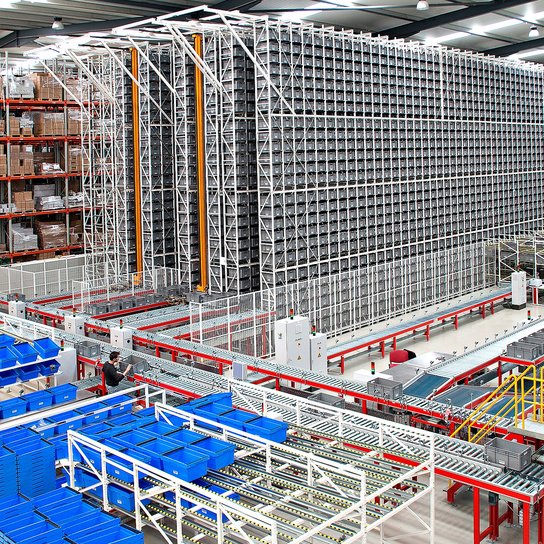

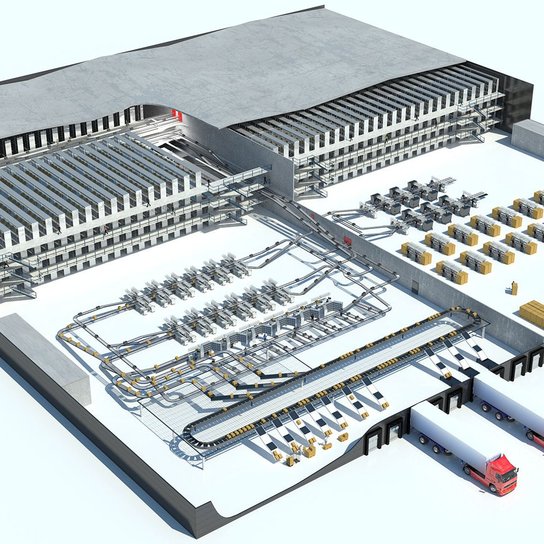

Körber has the knowledge, experience, and integrated hardware and software capabilities to meet your specific goods receiving and processing needs. Our robotic and automated applications span across the entire offloading, moving, checking and storage process – from voice-directed forklifts, autonomous mobile robots and conveyor systems to automated storage and retrieval applications for pallets and small goods.

We design stacker crane and pallet shuttle solutions optimized to the size and shape of your premises and the characteristics of your inbound flows. Our solutions make it quick and easy to place goods onto high- density racking, then retrieve them when needed. We tailor our automated storage and retrieval systems to meet your business challenges, whether they are a high volume of product throughput, space constraints, or the complexity of your product range.

Key benefits

Existing sites

We analyze all the prerequisites and potential constraints of your existing facility and map them with the future requirements of your supply chain.