Both sectors face high customer expectations, a result of rapidly growing consumer demand. And both have complex and geographically diverse supply chains, with the need to source agricultural raw materials worldwide. This exposes their supply chains to risk from external influences, while consumers and regulators expect complete transparency.

Demand requires supply chains to be responsive, agile and able to fulfill orders reliably. Some products have specific expiration dates or need to be maintained at certain temperatures, which must be monitored throughout the distribution process.

Industry challenges

The health and wellness supply chain distributes products through both retail and direct-to-consumer channels. This broad spectrum of retailer profiles ranges from niche providers to multinationals. Order types and volumes are also diverse, from single direct-to-consumer items through to entire product ranges for large retailers.

This is compounded by the sheer volume of product types, which often have unique handling, storage and visibility requirements. Warehouse space is therefore at a premium, and streamlined picking and tracking processes are critical to maintaining efficient inventory management. Anticipating order demand and adapting order cycles are also essential to balancing stock levels and prioritizing shipments.

The Körber difference

Körber’s solution and process experience will help you manage the complex challenges within the health and wellness supply chain. Through them, you can integrate suppliers from different countries, optimize your goods receiving, warehousing and shipping processes, track products throughout the supply chain, and serialize high-value items.

You can address specific handling/storage and product expiration requirements through itemized reports too. And, by managing different fulfillment requirements through your transportation management system, you will meet the full spectrum of your customers’ distribution needs.

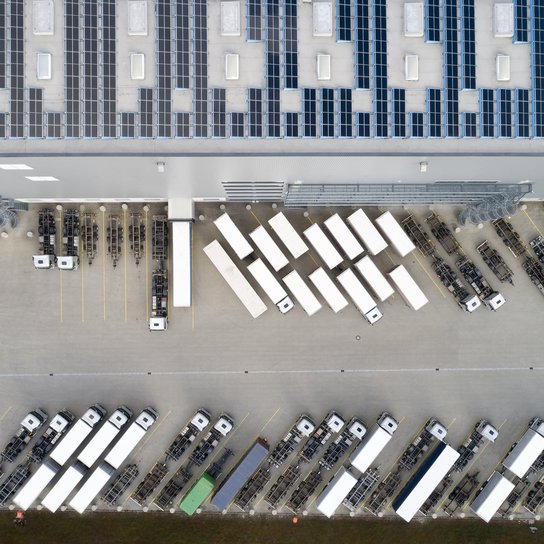

Combined with our comprehensive consulting services, our integrated warehouse (WMS), transportation (TMS) and yard (YMS) management systems drive efficiencies throughout your entire supply chain.

Our picking systems are supported by voice-directed technologies, intelligent order linking and multiple order batch picking. These give your warehouse staff clear direction on where to go and what to pick, for improved speed and accuracy. Material handling efficiency can be increased too by integrating automation equipment such as intelligent lifting devices, conveyor networks and carousels, and technology like radio frequency identification.